How should you think about applications for AI/ML technology within your supply chain to maximize the return on investment?

Photo by Volodymyr Hryshchenko on Unsplash

Background

Supply chain optimization is a vast area of research. There is a plethora of use cases within supply chains that would benefit from the application of AI/ML technology. Oftentimes, organizations struggle with where and how to start in this space. Supply chain executives are typically looking for areas where to invest the time and effort of their teams (which are already stretched) to derive the most value from these approaches. In this article, we explore a small but diverse set of use cases that can serve as a starting point for a supply chain organization’s foray into AI/ML. Supply chain leaders can expect to gain a high degree of cost and efficiency improvements from these applications.

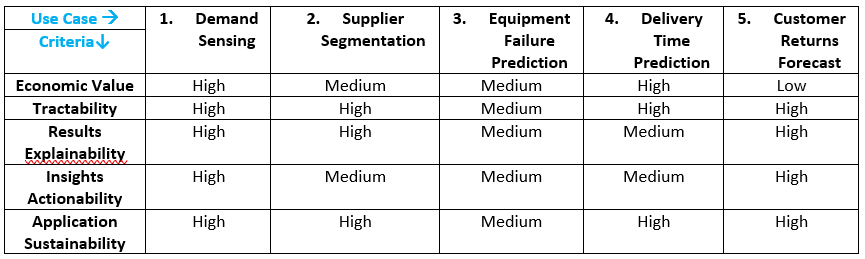

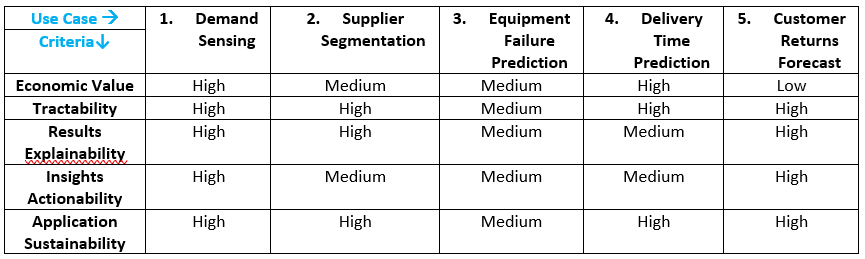

We divide supply chain management into five components: Plan, Source, Make, Deliver, Reverse Logistics and outline uses cases of Demand Sensing, Supplier Segmentation, Equipment Failure Prediction, Delivery Time Prediction, Customer Returns Forecast that map to the five components. Applying the criteria of economic value, tractability, results explainability, insights actionability, and application sustainability, qualitatively across the use cases, we also assess the overall benefit of implementing each use case.

Use Case Exploration

An Intelligent Supply Chain integrates data, automation, and advanced analytical technologies to bring efficiencies and reduced costs to different parts of the supply chain. It can be a source of strategic advantage to an organization by enhancing customer experience. It is typically supported by a combination of optimization and AI/ML technologies. We explore five use cases mapping them to five elements of supply chain management: Plan → Source → Make → Deliver → Reverse Logistics.

1. Short-term demand sensing (Plan): Inventory management is a critical supply chain activity. Working capital and storage costs are tied to inventory levels, which in turn, are dependent on accurately forecasting demand among other factors. A high level of forecast accuracy helps to reduce inventory costs and stock outs by driving the manufacture of the right quantity of product at the right location at the right time. This helps optimize inventory in warehouses reducing safety stock levels, thereby reducing costs, while avoiding stock outs that may lead to long-term business and revenue losses. An AI enabled application can identify patterns in customer orders and correlate certain leading indicators to the short-term demand to be more accurate than from traditional methods. With real-time orders information, we can automate demand predictions for the current and next month that are refreshed regularly.

2. Supplier segmentation (Source): Large organizations may have hundreds or thousands of suppliers that form an integral part of their supply chain. Different raw materials in varying quantities are sourced from suppliers. To reduce cost of procurement while increasing reliability of supply, it would be helpful to apply different strategies to different suppliers. Clustering suppliers into a few key groups would be beneficial in this regard given large number of suppliers. This type of segmentation will enable targeted contract negotiations on raw material prices, volumes and supply timing to optimize spend. An AI enabled application can segment suppliers based on features such as volume, price, strategic relationship, reliability to enable sourcing specialists to adopt similar procurement strategies for suppliers within a cluster. This segmentation can be refreshed on a monthly or quarterly basis to account for supplier changes.

3. Equipment failure predictions (Make): Unplanned downtimes due to reliability failures are common in manufacturing operations. These tend to stress product inventory positions and can lead to delays in customer fulfilment. Predicting when such downtimes may occur can help a facility either take actions to mitigate the risk of equipment failure or prepare in advance by building up inventory to account for the downtime. These predictions and consequent mitigation actions can help avoid stock outs and lost revenues and as well as drive investment in preventative maintenance options to avoid costly repairs. An AI enabled application can correlate equipment failures to key measurements (such as throughput, pressure, temperature etc.) for days or weeks leading up to an unplanned equipment failure and provide insights on the timing of failures. Depending on the granularity of measurements, the application may be run every day or every few days to assess the risk of failures.

4. Delivery time prediction (Delivery): On-time delivery to customers is a key metric to gauge performance of supply chains that directly impacts customer experience. Organizations measure this metric and actively attempt to improve it based on historical delay trends. Being able to predict delivery times accurately can help get the product to the customer at the requested time, thereby avoiding poor customer experience and lost business consequently and avoid penalties and other charges due to late deliveries. An AI enabled application can be used to predict delivery times based on start day and time, season, carrier, source, and destination among other attributes. Such a prediction for each shipment will enable keeping the customer informed and enhance customer experience and retention. Furthermore, this presents an opportunity to optimize the routes and select the better performing carriers.

5. Customer returns forecast (Reverse Logistics): A percentage of sales is returned by customers for a variety of reasons including not meeting quality specifications or delays in shipping. To prepare for returns shipments, storage and processing, companies need to have an accurate estimate of volume of products coming back. This will help in reducing storage and processing costs. An AI enabled application can provide an aggregate volume of returns as a function of past several weeks of customer shipments. This prediction can be updated on a weekly basis.

Use Case Prioritization

We view these use cases through the lens of five key criteria: economic value, tractability, results explainability, insights actionability, and application sustainability. Economic value includes any cost savings or loss of revenue avoidance. Tractability refers to availability of data and a robust AI/ML approach to provide predictions in a reasonable amount of time. Results explainability indicates how readily the observations and predictions can be explained to stakeholders using business drivers. Insights actionability characterizes the extent to which the organization can act on the results of the AI/ML application. Finally, application sustainability describes the long-term viability of actively maintaining and refreshing the inputs for the AI application.

(i) Economic Value: We anticipate ‘High’ economic value for Demand Sensing and Delivery Time Prediction due to the sheer volume of shipments. The sporadicity in taking actions for Supplier Segmentation and Equipment Failure Prediction lead to ‘Medium’ valuation while the relative lower volumes encountered in customer returns has driven the choice of ‘Low’ valuation.

(ii) Tractability: With the use case data size and computational power at our disposal, most of the use cases are expected to be ‘High’ tractability except for Equipment Failure Prediction, that may be data limited if failures do not occur very frequently.

(iii) Results Explainability: A recommended application of multiple linear regression for Demand Sensing and Customer Returns Forecast yields a ‘High’ explainability rating. An unsupervised method (e.g. k-means clustering) when applied to Supplier Segmentation can show which features are close in each cluster and hence the explainability has been marked as ‘High’. Application of more complex ensemble methods (e.g. Random Forest, Xgboost) for Equipment Failures Prediction and Delivery Time Prediction lead to ‘Medium’ explainability.

(iv) Insights Actionability: Actionability is marked ‘High’ for Demand Sensing and Customer Returns Forecast since it is an internal decision to change production and processing based on forecast changes, while actioning Delivery Time Prediction and Supplier Segmentation insights would require negotiation with external parties including carriers and suppliers, where we may have limited maneuverability. For Equipment Failures Prediction with a ‘Medium’ actionability rating, we may be able to take action to reduce risk but may not be able to drive failures to zero entirely.

(v) Application Sustainability: This is assumed to be high for four out of the five use cases since data may be generated at an appropriate pace allowing for frequent refreshes of the AI/ML application except for Equipment Failure Prediction, which may be data limited.

Looking across these use cases as summarized in the table below, Demand Sensing scores highest across all these criteria — the recommendation in this instance would be to start with an AI/ML application for this use case.

Use case qualitative scores against multiple criteria

Conclusion

The application of AI/ML techniques for supply chain and business optimization is still a nascent area in many industries. It is not unreasonable to take a “crawl, walk, run” approach towards integration of AI/ML into operations. Demonstrating the efficacy of AI/ML in generating value for a team via “low-hanging fruit” can have a flywheel effect. It is critical, though, to build on smaller successes towards a sustainable longer-term business model, where AI/ML is embedded in every aspect of the value chain.

Thanks for reading. Hope you found it useful. Feel free to send me your comments to rkumar5680@gmail.com. Let’s connect on LinkedIn

Getting Started with AI/ML to Build Intelligent Supply Chains was originally published in Towards Data Science on Medium, where people are continuing the conversation by highlighting and responding to this story.

Photo by Volodymyr Hryshchenko on Unsplash

Background

Supply chain optimization is a vast area of research. There is a plethora of use cases within supply chains that would benefit from the application of AI/ML technology. Oftentimes, organizations struggle with where and how to start in this space. Supply chain executives are typically looking for areas where to invest the time and effort of their teams (which are already stretched) to derive the most value from these approaches. In this article, we explore a small but diverse set of use cases that can serve as a starting point for a supply chain organization’s foray into AI/ML. Supply chain leaders can expect to gain a high degree of cost and efficiency improvements from these applications.

We divide supply chain management into five components: Plan, Source, Make, Deliver, Reverse Logistics and outline uses cases of Demand Sensing, Supplier Segmentation, Equipment Failure Prediction, Delivery Time Prediction, Customer Returns Forecast that map to the five components. Applying the criteria of economic value, tractability, results explainability, insights actionability, and application sustainability, qualitatively across the use cases, we also assess the overall benefit of implementing each use case.

Use Case Exploration

An Intelligent Supply Chain integrates data, automation, and advanced analytical technologies to bring efficiencies and reduced costs to different parts of the supply chain. It can be a source of strategic advantage to an organization by enhancing customer experience. It is typically supported by a combination of optimization and AI/ML technologies. We explore five use cases mapping them to five elements of supply chain management: Plan → Source → Make → Deliver → Reverse Logistics.

1. Short-term demand sensing (Plan): Inventory management is a critical supply chain activity. Working capital and storage costs are tied to inventory levels, which in turn, are dependent on accurately forecasting demand among other factors. A high level of forecast accuracy helps to reduce inventory costs and stock outs by driving the manufacture of the right quantity of product at the right location at the right time. This helps optimize inventory in warehouses reducing safety stock levels, thereby reducing costs, while avoiding stock outs that may lead to long-term business and revenue losses. An AI enabled application can identify patterns in customer orders and correlate certain leading indicators to the short-term demand to be more accurate than from traditional methods. With real-time orders information, we can automate demand predictions for the current and next month that are refreshed regularly.

2. Supplier segmentation (Source): Large organizations may have hundreds or thousands of suppliers that form an integral part of their supply chain. Different raw materials in varying quantities are sourced from suppliers. To reduce cost of procurement while increasing reliability of supply, it would be helpful to apply different strategies to different suppliers. Clustering suppliers into a few key groups would be beneficial in this regard given large number of suppliers. This type of segmentation will enable targeted contract negotiations on raw material prices, volumes and supply timing to optimize spend. An AI enabled application can segment suppliers based on features such as volume, price, strategic relationship, reliability to enable sourcing specialists to adopt similar procurement strategies for suppliers within a cluster. This segmentation can be refreshed on a monthly or quarterly basis to account for supplier changes.

3. Equipment failure predictions (Make): Unplanned downtimes due to reliability failures are common in manufacturing operations. These tend to stress product inventory positions and can lead to delays in customer fulfilment. Predicting when such downtimes may occur can help a facility either take actions to mitigate the risk of equipment failure or prepare in advance by building up inventory to account for the downtime. These predictions and consequent mitigation actions can help avoid stock outs and lost revenues and as well as drive investment in preventative maintenance options to avoid costly repairs. An AI enabled application can correlate equipment failures to key measurements (such as throughput, pressure, temperature etc.) for days or weeks leading up to an unplanned equipment failure and provide insights on the timing of failures. Depending on the granularity of measurements, the application may be run every day or every few days to assess the risk of failures.

4. Delivery time prediction (Delivery): On-time delivery to customers is a key metric to gauge performance of supply chains that directly impacts customer experience. Organizations measure this metric and actively attempt to improve it based on historical delay trends. Being able to predict delivery times accurately can help get the product to the customer at the requested time, thereby avoiding poor customer experience and lost business consequently and avoid penalties and other charges due to late deliveries. An AI enabled application can be used to predict delivery times based on start day and time, season, carrier, source, and destination among other attributes. Such a prediction for each shipment will enable keeping the customer informed and enhance customer experience and retention. Furthermore, this presents an opportunity to optimize the routes and select the better performing carriers.

5. Customer returns forecast (Reverse Logistics): A percentage of sales is returned by customers for a variety of reasons including not meeting quality specifications or delays in shipping. To prepare for returns shipments, storage and processing, companies need to have an accurate estimate of volume of products coming back. This will help in reducing storage and processing costs. An AI enabled application can provide an aggregate volume of returns as a function of past several weeks of customer shipments. This prediction can be updated on a weekly basis.

Use Case Prioritization

We view these use cases through the lens of five key criteria: economic value, tractability, results explainability, insights actionability, and application sustainability. Economic value includes any cost savings or loss of revenue avoidance. Tractability refers to availability of data and a robust AI/ML approach to provide predictions in a reasonable amount of time. Results explainability indicates how readily the observations and predictions can be explained to stakeholders using business drivers. Insights actionability characterizes the extent to which the organization can act on the results of the AI/ML application. Finally, application sustainability describes the long-term viability of actively maintaining and refreshing the inputs for the AI application.

(i) Economic Value: We anticipate ‘High’ economic value for Demand Sensing and Delivery Time Prediction due to the sheer volume of shipments. The sporadicity in taking actions for Supplier Segmentation and Equipment Failure Prediction lead to ‘Medium’ valuation while the relative lower volumes encountered in customer returns has driven the choice of ‘Low’ valuation.

(ii) Tractability: With the use case data size and computational power at our disposal, most of the use cases are expected to be ‘High’ tractability except for Equipment Failure Prediction, that may be data limited if failures do not occur very frequently.

(iii) Results Explainability: A recommended application of multiple linear regression for Demand Sensing and Customer Returns Forecast yields a ‘High’ explainability rating. An unsupervised method (e.g. k-means clustering) when applied to Supplier Segmentation can show which features are close in each cluster and hence the explainability has been marked as ‘High’. Application of more complex ensemble methods (e.g. Random Forest, Xgboost) for Equipment Failures Prediction and Delivery Time Prediction lead to ‘Medium’ explainability.

(iv) Insights Actionability: Actionability is marked ‘High’ for Demand Sensing and Customer Returns Forecast since it is an internal decision to change production and processing based on forecast changes, while actioning Delivery Time Prediction and Supplier Segmentation insights would require negotiation with external parties including carriers and suppliers, where we may have limited maneuverability. For Equipment Failures Prediction with a ‘Medium’ actionability rating, we may be able to take action to reduce risk but may not be able to drive failures to zero entirely.

(v) Application Sustainability: This is assumed to be high for four out of the five use cases since data may be generated at an appropriate pace allowing for frequent refreshes of the AI/ML application except for Equipment Failure Prediction, which may be data limited.

Looking across these use cases as summarized in the table below, Demand Sensing scores highest across all these criteria — the recommendation in this instance would be to start with an AI/ML application for this use case.

Use case qualitative scores against multiple criteria

Conclusion

The application of AI/ML techniques for supply chain and business optimization is still a nascent area in many industries. It is not unreasonable to take a “crawl, walk, run” approach towards integration of AI/ML into operations. Demonstrating the efficacy of AI/ML in generating value for a team via “low-hanging fruit” can have a flywheel effect. It is critical, though, to build on smaller successes towards a sustainable longer-term business model, where AI/ML is embedded in every aspect of the value chain.

Thanks for reading. Hope you found it useful. Feel free to send me your comments to rkumar5680@gmail.com. Let’s connect on LinkedIn

Getting Started with AI/ML to Build Intelligent Supply Chains was originally published in Towards Data Science on Medium, where people are continuing the conversation by highlighting and responding to this story.